In the general concept of this word. Instead, piles are driven to a certain depth along the perimeter and under future walls. But sometimes there is a danger that they will begin to “walk” when the ground settles. How to protect yourself from this problem? In such a case, a method has long been invented that will help avoid this disaster, and it is known as a grillage. What it is, how to do it and how difficult such work is - these are the questions we will understand today. And let's start, of course, with general information.

Read in the article

Grillage - what is it and what is it intended for?

To begin with, it makes sense to understand what a grillage is, what exactly is included in this concept. In essence, this is a special strapping of driven or screwed foundation piles, which can be made of any material. But, for example, it is completely optional. In such structures, its role is taken over by the lower crown of logs.

It should be noted that the strength of a pile foundation with a grillage is many times higher than without it. Sometimes it happens that you can’t do without it at all. It’s interesting that many people doing construction on a site and making a grillage don’t even know what it’s called.

At the same time, some come up with their own names for such work, while others even classify it as the foundation or the building itself. Meanwhile, this is a separate intermediate and structurally necessary stage. And then, if you ask how the work was done, they may even be surprised: “Grillage foundation? What is this anyway? I have ordinary piles.” We hope that after today’s review our readers will not have such situations.

What material can be used to make a grillage for a pile foundation?

The grillage can be made of various materials. It all depends on the purpose and size, as well as on the ground on which it will be located. He can be:

- Metal– various T-beams and I-beams are used;

- Wooden– it can be either logs;

- Concrete or reinforced concrete- for this purpose, formwork is made, which is filled with mortar.

Let's look at these types in more detail.

Manufacturing of a pile foundation with a monolithic grillage and its features

The monolithic grillage itself can be of two varieties:

- - this will connect all the foundation piles with a single foundation;

- – the piles will be connected along the perimeter and load-bearing walls with a strip. It turns out something like a raised, familiar foundation.

Manufacturing a pile grillage with a monolithic slab-type ceiling is more expensive than a strip-type one, but the structure will be much stronger and more reliable.

Important information! The reliability and quality of the finished grillage will depend on the correctness of the drawn up project with the distribution of the subsequent load, the choice of the type of structure and the installation of the formwork. The same factors affect concrete consumption.

But despite all the strength of a monolithic grillage on piles to compression, such a foundation does not tolerate fracture loads well. Therefore, when constructing such structures on marshy, “floating” soils, it is better to choose a different material.

To pre-calculate the costs of performing such work, you can use documents such as state elemental estimate standards for construction work (GESN). The construction of a monolithic grillage is clearly stated in them, including not only the material, but also the operating hours of mechanized devices, if they are needed.

Related article:

If there are difficulties with reliable support on the land, choose a pile foundation structure. Using the materials in this article, anyone can prepare a project independently without errors.

Construction of a wooden grillage as the most convenient way to make a foundation

As already mentioned, the first crown of logs in a log house can serve as a wooden grillage on a columnar foundation. However, if it is assembled, for example, then it is installed separately. The best shape for this would be a beam whose dimensions can support the weight of the structure.

Important tip! The timber grillage must be impregnated as thoroughly as possible with a special composition that prevents rotting and protects against mold, mildew and insects. Nowadays, the range of similar products on the shelves of construction stores is quite large. In extreme cases, you can use regular drying oil. Remember that the service life of the foundation, and therefore the entire structure as a whole, depends on the quality of processing.

Installing a grillage made of timber on a columnar foundation is the easiest and most... At the same time, wood can withstand fracture loads better, and therefore such structures are the most common. Of course, if you plan to build a two- or three-story building, it is better to use a more solid foundation, but for a one-story house such a grillage will be quite sufficient.

Metal base for buildings - in what case is such a material suitable?

A metal grillage is also not bad, but its construction is more expensive than a wooden grillage. The fact is that it is quite problematic to manually lift heavy T-beams or I-beams onto piles, which means you will have to order equipment. And this means additional costs and time. In addition, the metal is susceptible to corrosion, so additional processing will be required. If you do not adequately prepare the material before coating it with anti-corrosion substances, you will end up with empty work and all the protection will begin to peel off within two to three years.

Despite the fact that the metal itself is quite strong in both compression and fracture, many may be deterred from using it by the complexity of installation. Skills will be needed here, because a lot also depends on the quality of the seam.

Important! Welding seams require special and more careful processing. They are more susceptible to corrosion than other parts of the grillage.

Types of grillage, their purpose and possibility of use in various situations

We have already mentioned the types of monolithic grillage in general terms. Now it's time to talk about this in more detail. Perhaps this information will help the home craftsman decide for himself the main question - where to start building a foundation.

Installation of a strip foundation with a grillage - nuances of the work

Let's start with the fact that if it is assumed, then the piles under it will be driven or screwed into the ground in a special way. And there is an explanation for this. The fact is that the pitch of the piles in a strip grillage should be somewhat smaller than what is allowed in a slab grillage.

Important information! The more often the supports of a pile foundation with a strip grillage are located, the better, but you shouldn’t be too partial either. There is no need for fanaticism in this matter.

You need to understand that the distance between the piles will depend largely on the soil. After all, according to the laws of physics, the fewer piles are located under the grillage, the greater the pressure the structure will exert on them. Also, when pouring piles (if the bored option is chosen), you need to remember that this stage is mandatory.

Grillage for a fence - how the work to complete it is carried out

The grillage does not imply any difficulties in the device. It can be monolithic, wooden or metal. The main task here is to calculate the installation of piles in such a way that one of them is necessarily under the support, without which it cannot be built. For example, if it is decided that one section will be 3 m long, and the grillage is made of timber, it makes sense to drive piles every one and a half meters. And with two-meter sections, intermediate support points may not be required. But this is if concrete sections are not planned, which weigh quite a lot. In this case, it is better to make the grillage from metal or monolith.

Pile bush - what is it and what kind of grillage is needed for it

In simple terms, a bush is several piles united by one grillage. For example, you can take the same one, which passes through a wetland with unstable soil. Then, in some places the piles may “float”. There is only one thing left to do - use a pile bush.

In order to bring this to life, there is no need to install one pile in an unstable place, as was the case with the direct fence project. Here you should act a little differently. We mark in this place an isosceles triangle with sides of 0.5 m each (for example) so that its center is exactly on a straight line. After this, we drive 3 piles into the corners and connect them with a grillage. Of course, more work is added, but the strength of such a structure will be many times higher. Thus, a columnar foundation with a grillage for a pile bush will be much more resistant to soil movement, and therefore more reliable.

Differences in pile-grillage foundations by type of underground supports

Based on the type of piles, the following foundation technologies are distinguished:

- Bored grillage;

- Foundation on.

If you pay attention to the structure of the grillage itself, you will not be able to find any differences. The whole point here is in the design and installation of piles for the foundation. This is what we will now dwell on in more detail.

Technology of bored piles with grillage and how to do it yourself

A bored foundation with a grillage is a more expensive, but at the same time more durable and stable option. If the depth of the piles is not too great, it is quite possible to do all the work yourself without spending money on paying professionals.

We'll talk about the full step-by-step instructions a little later, but now we'll look at the technology in general terms. The deepening itself can be done using a garden drill, but if you need a decent depth or the soil does not allow you to do this work yourself, you will have to call a technician. The main task here is to correctly and accurately mark where the piles will be located.

Reinforcement is quite simple. Several rods are lowered into the drilled hole so that they stick out from above by at least half a meter. This will be useful later when constructing the grillage. No special strapping is required for the rods, but if you wish, it won’t hurt. This is how the grillage is made on bored piles. Of course, a lot of intermediate work is not mentioned, but in general terms it should be clear. It is also impossible to do without insulation of bored foundations with a grillage, but everything has its time. We will definitely explain all these steps in detail.

Grillage on screw piles - its pros and cons

There is an easier way than drilling wells and... If you plan to build an ordinary one, then there is no need to make such a complex and strong foundation (although it should also have special characteristics). In this case, a pile-screw grillage would be most appropriate. The technology is like this. Not too thick metal pipes, which are used as piles, have at the end a kind of pointed small auger. With its help, scroll the pipe and drive the pile to the required depth. If it is not too large, this can be done using a crowbar. If the soil is hard or rocky, and you need to go deep enough, you will have to call in special equipment.

After the piles are immersed to the required depth, they are combined with a grillage made by any of the known methods.

Important information! High buildings of 2-3 floors cannot be erected on a pile-screw grillage, especially if the soil is unstable.

Related article:

This technology is used to speed up the construction of not too heavy buildings and other architectural structures. In the article you will find step-by-step instructions for constructing the structure and useful advice from experts.

The main dimensions of grillages - how their dimensions differ

Starting with this difficult topic, we can say that detailed information on the rules for calculating the height of grillage foundations, as well as other dimensions, is unlikely to be useful to the average person. The fact is that even knowing all the formulas necessary for calculations, a person who is not associated with , is unlikely to be able to calculate everything correctly. That is why we will try to outline such a topic as the dimensions of the pile foundation grillage as simply and in general terms as possible.

Let's try to understand how the load will be distributed after the construction of the building is completed. If we turn to the exact sciences, then with the correct construction of the structure, the load should be evenly distributed over the grillage, which (in turn) will distribute it across all involved piles. But it should be understood that if the structure contains vertical load-bearing beams, they must be located directly above the pile. In this case, the load will be distributed so that not the most powerful grillage can easily withstand it. Experts can freely calculate what dimensions are needed for a pile foundation in a cross-section of all dimensions.

Important tip! It is quite possible to do without the help of engineers in such work, provided that a bathhouse, a good-quality barn or a storage room is being built. If you plan to build a permanent house, then it is better to involve professionals.

What is the difference between the series of pile grillages: their most famous manufacturers

In principle, it is possible to purchase ready-made grillages, but here you need to study quite a lot of documentation. The fact is that there are quite a lot of grillage series, and each one differs from each other in strength, size, corrosion resistance and many other parameters.

The most famous manufacturer of reinforced concrete grillages from 35 tons is the Russian company LLC SK PromTehStroy. But they only make such large grillages to order. For smaller ones, no prior arrangement is required; they are always in stock. As for the production of reinforced concrete grillages from 50 tons, you can order similar ones from DSK Rostverk LLC, and it will cost quite a tidy sum.

But for personal construction on the site, much smaller dimensions are required, and therefore it is worth considering a series of grillages on Russian markets, which can be purchased in almost every city.

| Series | Size, mm | Weight, t | Average cost, rub. |

| FL 8-24-3 | 2380x 800x300 | 1,15 | 3 000 |

| FL 10-24-3 | 2380×1000x300 | 1,38 | 3 800 |

| FL 12-24-3 | 2380×1200x300 | 1,63 | 5 005 |

| FL 14-24-3 | 2380×1400x300 | 1,90 | 6 080 |

| FL 16-24-3 | 2380×1600x300 | 2,15 | 7 120 |

| FL 28-12-3 | 2800×1180x500 | 2,82 | 10 200 |

| FL 32-12-3 | 3200×1180x500 | 3,23 | 14 050 |

It turns out that purchasing such products is not difficult. But it is worth understanding that in this case you cannot do without a crane, and this is another expense item. The typical grillages for pile foundations that were presented are not the full range of companies involved in their manufacture. These series are given in order to generally understand the cost of finished products and compare costs (when planning to make your own grillage).

Construction of a pile grillage: basic provisions and rules

According to the requirements, concrete can also be considered a grillage, and therefore it cannot be ignored. Such a pile-grillage foundation is designed in such a way that the formwork is installed only along the side walls. Its lower part is replaced by soil.

Important tip! If you plan to remove the side walls of the formwork after the grillage has dried, then they should be coated with special compounds. If it is not possible to purchase such mixtures, it is possible to use ordinary grease instead.

You can roughly calculate a pile foundation with a grillage yourself, but (as already mentioned) you shouldn’t do this if you don’t have similar experience. Commercial buildings are not covered by this ban. Compliance and execution of the grillage according to the scheme is mandatory; even the slightest deviation from the dimensions is not allowed.

Now regarding the distances between the piles. You can calculate it for a long time or make it as small as possible (which will be wrong), but there is another option. According to SNiP, the distance between piles in a grillage should be at least a meter. If you plan to build a structure without a project, for insurance you can install piles at a distance of 1 m from one another or a little wider, depending on the load-bearing vertical beams.

Advice! Knowing from the design the size of the walls, roof, material that will be used during construction and the volume of the grillage, it will not be difficult to calculate the load that the foundation will have to withstand. To do this, you just need to use the calculator presented below.

It is not always possible and not in all situations to use traditional foundations, including slab foundations. In some situations, they become too expensive: their arrangement can take up to 40-50% of the cost of the entire building. This usually happens during construction in areas with a large freezing depth (below 2 meters) or on unstable, weak-bearing soils. In such cases, a pile-grillage foundation is often the best solution.

What is a pile-grillage foundation

Everyone probably imagines a pile foundation: it is a number of piles buried in the ground to the level of the load-bearing layer or below the freezing level. In its pure form, this type of foundation is rarely used. This is due to the peculiar design, which does not allow the load from the house to be redistributed between the piles. Therefore, pile foundations are mainly made for log buildings made of logs or timber, and sometimes for frame buildings. These types of building materials, due to their characteristics, themselves redistribute the load. They are not compatible with houses made of other materials.

But their improved form - a pile foundation with a grillage - is free of many disadvantages and can be used for both brick and block buildings. In them, all the supports are tied using a tape made of metal or reinforced concrete (concrete) into a single structure. This tape is called a grillage.

A grillage is a part of the foundation that connects the pile heads and serves as a support for the walls. It is the grillage that receives and, due to the closed structure, redistributes the load, transferring it to the piles. It can be metal, wood, concrete or reinforced concrete. According to the type of execution, concrete (reinforced concrete) grillages are low and high.

The high grillage is above ground level. Most often it is made of metal - large-section channels or square metal pipes. They also make such a grillage out of concrete, but its design is more complicated: you have to figure out how to fill the tape at a distance from the ground.

How does a grillage work and what does it give?

Any house in different parts will have different loads: decoration, furniture, sanitaryware, other things are placed unevenly. Consequently, the load from its different parts will be different. The grillage takes on these uneven loads and redistributes them. The “leveled” load is already transferred to the piles.

What is the difference between pile and pile-grillage foundations (to enlarge the size of the picture, right-click on it)

Why is this good? The fact is that with the same load on the piles, there is less chance that they will settle unevenly. And uneven shrinkage leads, as is known, to cracks in the foundation and walls. Therefore, the pile-grillage foundation is more stable. Although the main disadvantage of pile foundations remains: we cannot know what kind of soil is under each of the piles. Therefore, it is unrealistic to predict their behavior. That is why architects are not very fond of them: it is impossible to guarantee long-term operation of the house.

Strip foundation on piles

Low grillages are more predictable in this regard. They usually start below ground level and are cast from reinforced (or not - depending on the project) concrete. Moreover, the reinforcement of the piles is connected to the reinforcement of the grillage.

In this case, the grillage is a shallowly buried strip foundation and it is made using the same technology. It differs in that it has a rigid connection with the piles, which significantly increases the reliability and stability of the structure. Such foundations are also called strip foundations on piles or pile-strip foundations. This design is almost ideal: it combines the advantages of pile and strip foundations, largely compensating for their disadvantages.

Construction of a pile-strip foundation (to enlarge the size of the picture, right-click on it)

How does he work? The load from the house is transferred to the belt. Thanks to the presence of longitudinal reinforcement, it is redistributed over the entire area. Since the tape also rests on the ground, part of the load is transferred to it, the rest falls on the piles. In this case, the load and shrinkage are uniform: they are “evened out” by the tape.

In winter, when heaving forces begin to affect the foundation, all the advantages of a pile-strip foundation appear. If the house is located on heaving soils, their depth is below the freezing level, it is very difficult to imagine conditions under which the house will warp or it will shrink unevenly.

When heaving forces act on the tape, the “heels” of the piles, and they themselves, do not allow the soil to move the foundation. Therefore, strip-pile foundations are an excellent choice on highly heaving soils. The costs are much higher than when constructing a conventional pile foundation, but much lower than when constructing a strip below the freezing depth.

When can it be used

Sometimes it’s even simpler: they start from the lowest cost. But you should always remember that any type of pile foundation is less reliable than slab and strip foundations. And all because we cannot know exactly what kind of soil is under each of the piles. That is why, when calculating parameters, an increased safety margin is included in the design. Not 1.2, as is usually believed, but 1.4. And still, no one can guarantee anything.

Which piles to use

Any piles can be used in pile-grillage foundations. They are selected based on the soil and the planned load of the house. Piles are made of metal, concrete, and sometimes wood. They can have a round or square cross-section. They also differ in the installation method:

In private construction, bored piles are most often used. They are especially popular in the construction of summer houses or baths. They can also be used in the construction of small houses. But if dachas and bathhouses can be built without calculations, then when building a house it is very advisable to order a project.

Different piles come in different shapes: square or triangular, round filled and round hollow, sometimes complex shapes are developed specifically for the project. Based on how piles transfer load to the ground, they are:

Hanging piles have a large lateral surface and a significant part of the load (up to 60-70%) is transferred with its help. They are used if the bearing capacity of the soil at the achieved level is not enough to withstand the entire load, and further deepening is impractical. In this case, the presence of a “heel” changes almost nothing: the main load is transmitted by the surface, and not by the tip of the pile.

Rack piles, on the contrary, transfer most of the load through the tip. In this case, the side walls are undeveloped and smooth, and it makes sense to expand at the end of the pile. One of the types of this type is . They have a cylindrical extension at the bottom, which is why they transfer the load to a larger area. Also, the heel prevents heaving forces from lifting the foundation.

Location of piles in the grillage

In most cases, supports in the ground are placed vertically. Sometimes an inclined installation may be required, and several pieces in one place. This method is used if horizontally directed forces may arise. For example, during construction on sloping areas.

Piles can be located pointwise - under supports (columns, racks). This arrangement is typical when constructing canopies or installing roofs over open areas. Then the supports are placed exactly under the columns holding the roof.

For private houses with a small number of floors, the piles are placed in the form of a strip. They are placed in one row, sometimes in two or three, shifting them relative to each other. Sometimes in the most loaded parts, for example, in corners, under areas with a large planned load, they are placed in bushes: several pieces at a short distance from each other.

How to arrange a house plan yourself

When designing a pile foundation on your own, you usually proceed as follows. On a building plan drawn to scale, piles must be laid in the corners and at the intersections with the walls. If they are more than 3 meters apart from each other, intermediate supports are placed between them. It is advisable that the piles be located one from another at a distance of 2 to 3 meters.

The principle is simple, but you still need to determine the required area of the piles. And it needs to be calculated (or rather, selected).

Calculation of pile-grillage foundation

In order to be at least partially confident in the reliability of the foundation, it is advisable to at least approximately calculate it. To do this, you will need to do several not very complex calculations.

- The weight of the house is calculated (all materials and the approximate weight of the “filling” are taken into account).

- Based on the weight and safety factor, the required supporting area is determined.

- Since the piles have already been placed, we can count their number.

- Next we select the cross-sectional area of the piles. Since we know their number, multiplying by the selected area, we find out the total.

- We compare the obtained result with the reference area calculated earlier (point 4).

- If the area found in step 4 is larger than that calculated in step 2, the selected pile parameters are suitable for us.

- If it is less, we increase the planned cross-section of the piles, multiply again and compare. This is how we find the required area of the pile.

Sometimes it is more profitable not to increase the area of piles, but to install them more often. The calculation method does not change.

Load-bearing capacity of piles of different diameters in different soils (to increase the size of the picture, right-click on it)

The support area required for normal load distribution is calculated by the formula:

Where N is the bearing capacity of the soil (it can be taken from the table). The coefficient of 1.4 was applied due to the fact that pile foundations require a larger margin of safety: we do not know what kind of soil is under all the piles. Therefore, it is better to play it safe.

For more information on calculating the supporting area and calculating the mass of the house, watch the video.

Construction technology

So, you have a project ready, or you yourself have decided on the location of the piles, their parameters, the type and height of the grillage. Construction can begin.

Marking

First, the entire fertile layer of soil is removed, taken out to the garden or stored in one of the corners of the site. The area for the foundation is leveled. Then, using pegs and cords, the boundaries of the house are marked. Moreover, two cords are pulled, marking the outer and inner surfaces of the walls. Be sure to check the geometry by re-measuring and comparing all the diagonals in pairs.

After the marking is completed, you can mark the installation locations of the piles. We have them drawn on the plan and calculated, the distances between them are determined.

Schematic representation of the work procedure during the construction of a pile-grillage foundation with your own hands (to enlarge the size of the picture, click on it with the right mouse button)

Excavation and pouring of piles

How exactly the work will take place depends on the type of piles used. Most often, screw or bored piles are used when building a house.

Screws can be screwed in by hand. When twisting, their heads are aligned at the same level. It is more convenient to mark it with cords.

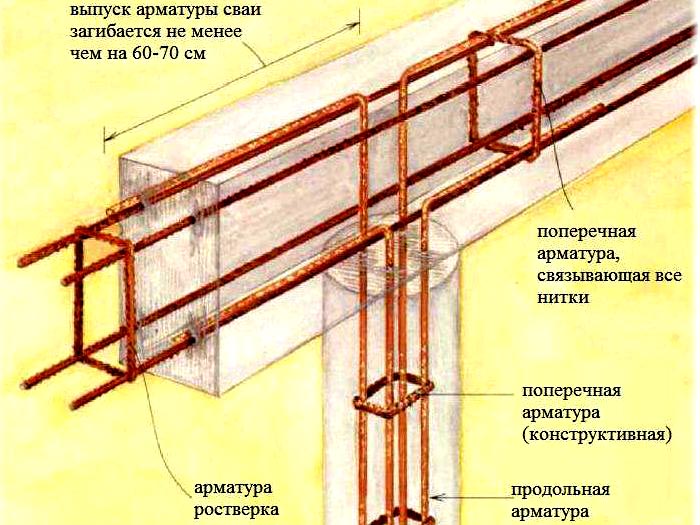

For drilling, you will need either special equipment or a hand drill of a suitable diameter. These devices drill holes in the right places. The selected formwork is lowered into the finished wells, and reinforcement is installed (four bars of ribbed reinforcement connected to each other). If the foundation is pile-strip, then the reinforcement must have an outlet of at least 60-70 cm. It will then be connected to the grillage. The last step in this stage is pouring the concrete.

The pile foundation is ready for installation of formwork for the grillage. In this case, formwork made of roofing felt or roofing felt, rolled several times, is used.

Grillage arrangement

If a metal grillage is selected, it is welded to the pile heads. When working, it is important to maintain strict horizontality: then the load will be transferred evenly.

To install a recessed reinforced concrete grillage (low), you will need to add crushed stone of a fraction of 20-60 mm and compact it with a vibrating platform. The minimum layer of crushed stone is 15 cm. To improve the bearing capacity of the soil under the belt, it is necessary to pour crushed stone in small layers (5 cm each) and thoroughly compact it with a vibrating platform. It will not be possible to compact well around the piles, but this is not so important.

Formwork is installed on this bedding. The width of the tape is slightly larger than the width of the walls, the height of the panels is made taking into account the required height of the base. Assembling the panels and installing stops exactly repeats the installation technology

Reinforcement is carried out in most cases in the same way as during the construction of a belt: two belts at the top and bottom made of ribbed reinforcement, transverse and vertical posts made of a smooth rod of smaller diameter. All reinforcement rules are preserved. Only the dressing with piles is added. The outlets of the reinforcement from the piles are bent: one row is tied to the lower belt, the second - to the top (do not forget to make the outlets of different lengths). They must be at least 50 bar diameters (if 12 mm reinforcement is used, you need to bend 600 mm (50 * 12 mm)). The reinforcement diagram for the pile abutment is shown in the figure.

Installation of embedded parts

At this stage, it is necessary to leave ventilation ducts and lay pipes and ducts through which utilities will be supplied (plumbing, heating, electricity, sewerage).

If this is not done, you will have to subsequently chisel the concrete. And this is a great evil for the foundation, because the integrity of the monolith is violated. So think through everything carefully: there will be no opportunity to redo it.

Pouring concrete

Concrete is not just poured. It is also vibrated. Without this process, it is very difficult to achieve uniformity and high strength. Therefore, processing foundation concrete with a vibrator can be considered a mandatory process.

If the air temperature after pouring concrete is around +20°C, then the formwork can be removed after four days. During this time, the concrete will gain approximately 50% of its design strength, which is enough to carry out the following work. If the temperature was around +10°, you will have to wait 10-14 days. At lower temperatures, conditions are considered wintry and the poured concrete requires insulation or heating.

Everything is ready for pouring concrete: the reinforced belt is tied, the formwork is set and secured (to enlarge the size of the picture, right-click on it)

For all their attractiveness, pile foundations have disadvantages:

- As already mentioned, due to the fact that it is impossible to determine what kind of soil is located under each of the piles, its behavior is almost impossible to predict.

- In such buildings it is impossible to install basements.

- With high grillages, it is necessary to somehow close the gap: animals and insects like to live there.

We will send the material to you by e-mail

Before building a house and deciding which foundation to create - or a pile foundation, novice builders are faced with such a concept as a grillage. Below we will look at what a grillage is and its necessity when constructing the foundations of a building.

General view of the monolithic structure

A grillage is a horizontally located element of the pile foundation of a structure (a kind of belt or cushion), which takes on the entire load of the building and, evenly distributing it, transfers it to the support columns. This is achieved by tying the piles into a complete structure. Since a grillage on a pile foundation increases the strength of the building, it is necessary to ensure sufficient rigidity for all connection points.

The advantage of such a foundation for a building is its durability, strength and the ability to build on sandy and clay soils, as well as on quicksand. In addition, due to the insignificant amount of preparatory work and the concrete mortar used, such a house foundation design is considered a less expensive option compared to other types of foundations.

To better understand what a grillage is, you need to know its classification into the following types:

- at the place of arrangement;

- on the building materials used;

- by constructive solution.

By location:

- Shallow. This is the optimal type of construction to obtain reliable stability. Since the base of the belt is located directly on the ground, the entire future load from the structure will be distributed not only between the piles, but also over the entire foundation.

- Recessed. In this case, part of the structure with a sole width of 50 cm or more enters the ground. These are used for the construction of multi-story buildings on unstable soils.

Video: grillage device for a wooden house

Metal belt for foundation

Metal sheathing is made of channel, I-beam or square profile and has high strength and rigidity. As a rule, this design is used when constructing pile-screw foundations for. The channel is installed on the heads of the supports and fixed by means of a welding connection.

A metal belt is used mainly in a hanging version. However, recently such structures have been used very rarely, since due to the heaviness of the material, the use of special lifting equipment is required, which is not economically profitable. In addition, the metal is at risk of corrosion processes.

Types and purpose of grillages

Grillage structures vary in type and purpose. When choosing the required design, many factors are taken into account.

Strip foundations with grillages

For buildings, a fairly strong and reliable support is pile foundations with a strip grillage, for the construction of which two technologies are used. One of them is used when arranging foundations above ground level, and the second is used at the stage of creating a lattice structure that takes on part of the load.

A strip foundation is the best option for constructing a foundation on slopes and areas with complex terrain, since it does not require complex preparatory work to plan the site using special equipment. This design is perfect for the construction of structures made of lightweight materials.

Using a strip foundation when building a house requires the following:

- Sand cushion, the thickness of which is 200-300 mm. It is created under a concrete frame and piles to protect them from the destructive effects of ground moisture.

- Waterproofing gratings and supports, for which polyethylene film, roofing felt or asbestos-cement pipes are used.

When arranging the foundation, it is necessary to carefully consider the strip grillage, as well as its thickness and other parameters.

For the fence

The installation of a grillage for fences is necessary for complete protection of the structure, which the plane of the fence cannot provide. The creation of the belt is due not only to provide protection from external factors, but also to ensure that, for example, pets cannot get out of the area. The reasons may be any, but the execution must always be of high quality, ensuring the strength and durability of the structure.

In principle, a grillage for a fence is practically no different from the belt used in arranging the foundations of houses. The same design and building materials are used here and similar functions are performed.

For pile foundation

The need to install a columnar foundation with a grillage is directly determined by the specific design of the building, its weight and the rigidity of the structure’s frame. To prevent the support columns from collapsing, they are bound with a monolithic reinforced concrete, metal or even wooden belt.

Several schemes for pile foundations of buildings are used in construction:

- Columns with a hanging belt are buried in the ground. This scheme is used in 90% of all pile foundations;

- The pillars rest on a crushed stone embankment without going deep into the ground. With this scheme, high rigidity of the base of the house is ensured, which makes it possible to minimize the likelihood of subsidence of the structure;

- No grillage. This option is used for the construction of small houses.

On a note! Supports for the columnar base of a building can be combined, for example, brickwork is combined with pouring concrete mortar or a base made of rubble. In principle, this does not change the properties of the foundation, but the arrangement process is greatly simplified and the cost is reduced.

Pile-grillage foundations

Grillage technology with bored piles

Arrangement of foundations with a grillage on bored piles is mandatory when constructing buildings on uneven terrain, slopes and unstable soils. These structures are the best option for the construction of both small houses and medium-sized permanent structures. Bored foundations with a grillage have a higher load-bearing capacity than monolithic and strip foundations, and they are cheaper.

Bored piles are able to withstand a load of about 1500 kg. To erect a medium-sized structure, you will need several dozen columns, the diameter of which can reach up to 150 cm and the length up to 40 m.

To arrange the base of the building, no major excavation work is required. Each pile is waterproofed with two layers of roofing felt or roofing felt and fixed in a non-freezing layer of soil. Waterproofing helps protect concrete from destruction and reduce soil pressure on supports.

Advantages of a foundation on bored supports:

The tops of the installed pillars are cut off at the same level, after which they are united by a common belt. A grillage on bored piles allows for uniform distribution of the load exerted by the weight of the structure throughout the entire base of the building. The construction of a pile-grillage foundation can be seen in the video below:

The disadvantage of this design is the fact that due to the presence of free space between the floor and the ground, a bored foundation with a grillage needs to be insulated. This leads to additional labor and material costs.

Grillage on screw piles

The advantage of foundations on screw piles is that their installation does not require excavation work, and they are usually used on clayey and heaving soils. After the supports are installed, their heads are cut to one level and a lattice belt is installed.

Monolithic reinforced concrete and concrete structures for screw piles are made extremely rarely, since this type of support is used for the construction of lightweight structures. Most often, a pile-screw grillage is made from a metal corner or channel.

Before installing the grillage on the heads, metal platforms are welded to them, the size of which should allow the axial displacement of the supports to be corrected. Next, all the piles are tied with a channel or angle, resulting in a strong and reliable structure.

Important! Before installing the foundation and grillage on screw piles, it is necessary to carry out anti-corrosion treatment of all metal structural elements. This will significantly increase the service life of the structure being built.

Main dimensions and dimensions

To create a strong and durable foundation, it is necessary to make the correct calculations. The shape and dimensions of the grillage used are determined by the design features of the building being constructed, the loads on the foundation, and the number and location of piles.

The grillage is created in the same way as the strip foundation structure. The height of the grillages for pile foundations directly depends on the level to which the structure should be raised from the ground, as well as on its weight. You can independently calculate a structure resting on the ground or slightly recessed. In the case of constructing a hanging belt, it is better to entrust the calculations to specialists, since they are very complex for a non-professional.

- B – minimum permissible height for belt support;

- M – weight of the structure of the structure without taking into account the supports used;

- L – belt length;

- R – soil strength at the surface of the earth.

Reinforcement frames for belts on a pile foundation are created in the same way as for construction on a strip foundation. The structure requires longitudinal (working), horizontal and vertical transverse reinforcement. The total cross-section of the longitudinal reinforcement must be at least 0.1% of the cross-section of the belt. To select the cross-section of each rod and their even number, an assortment of reinforcement is used.

Main manufacturers and standard series of pile grillages

For private or small buildings, you can make lattice belts yourself directly at the construction site, but when constructing industrial buildings, multi-story buildings, etc. use factory-produced designs. Among the main manufacturers of precast concrete grillages from 35 tons, the following companies can be distinguished:

- JSC APSC "Gulkevichsky" ;

- CJSC "OBD" ;

- JSC "T-Beton" ;

- LLC "LSR. Construction-Ural" ;

- LLC "ZKPD Tomsk House-Building Company" ;

- JSC "PZSP" .

| Series | Description | |

|---|---|---|

| Monolithic reinforced concrete grillages Series 1.411.1-1/89 | For the installation of foundations for prefabricated reinforced concrete columns of single- and multi-story industrial buildings of the II 20-1/70, II 20-2/70, II 20-3/70 series. | Structure supports of the II 20-1/70, II 20-2/70, II 20-3/70 series have a cross-section of 400*400 and 400*600 mm. and must be embedded into the foundation at 600 mm. |

| Series 1.011-6 | Made from heavy concrete class B 12.5 | Square piles 300*300 and 350*350 mm. |

| Series for metal grillage: 3.407.9-1581 | To operate the structure at temperatures: ● up to - 40˚C the grillage is made of carbon steel grade VSt 3, corresponding to GOST 380-71; ● below - 40˚C for the grillage, low-alloy steel grade 09G2S is used, which corresponds to GOST 19281-73 and 19282-73. |

|

The name used to designate typical grillages for pile foundations includes the mandatory letter indices RS and RB and serial numbers. Markings RS1 – RS5 are used on square supports, and RB – for rectangular piles.

Important! If it is necessary to order grillages from 50 tons, the concrete manufacturer must be chosen especially carefully to ensure the strength and durability of the entire structure.

Basic provisions for the design and calculation of a pile grillage

When installing a pile-grillage foundation, it is necessary to know the basic requirements for the grillage and carry out competent calculations of the entire structure. It is also necessary to have an as-built diagram for the grillages, which indicates all the main structural elements. An important point when designing the foundation of a building is the accurate calculation of the required number of supports for each specific type of structure. The calculations are based on the total weight of the structure and the bearing capacity of the soil. The mass of the house must be divided by the bearing capacity of the soil and we obtain the area of the designed foundation. To determine the safety factor, the foundation area should be increased by 30%. To calculate the required number of support columns, the area of the base must be divided by the volume of each pile, and the following conditions must be met:

- supports must be installed in all corners of the structure being constructed;

- piles are mounted at the intersection points of the building walls;

- According to SNIP, the distance between the piles in the grillage is 2-2.5 m.

The connection between the pile and the belt can be rigid or free. In the case of a loose connection, the heads of the supports enter the grillage to a depth of 50-100 mm. This type of fastening is suitable for centrally loaded support columns.

With a rigid connection, the pile head is broken and the reinforcement is exposed, after which it is embedded into a concrete or reinforced concrete grillage. This type of fastening is performed in cases where:

- the installation of pile foundations with grillages is carried out on unstable soils;

- horizontal loads are placed on the supports;

- combined or inclined supports are installed at the base;

- support columns work with pull-out loads.

Calculation example

Let's consider an example of calculating a pile foundation with grillages for a one-story brick house with a hip roof made of metal tiles. The building has two reinforced concrete floors with a thickness of 220 mm. The dimensions of the house in plan are 6*9 m, the thickness of the load-bearing walls is 380 mm. The total height of the floor is 3.15 m, from floor to ceiling – 2.8 m, and the total length of the partitions inside the building is 10 m (there are no internal walls in the rooms). The site contains a refractory mixture with a porosity of 0.5 and a depth of 3.1 m.

We pre-set the grillage width to 400 mm. and height 500 mm. The length of the support is 3 m, and the cross-section is 50 cm. We focus on the pitch of the support piles – 1.5 m. To determine the total number of piles, it is necessary to divide the length of the grillage by the pitch of the supports and add 1 (if necessary, round the resulting value down to the nearest whole number numbers – 30/1.5+1≈21).

- Support area, m 2 3,14*0,52/4 = 0,196

- Perimeter, m - 2*3,14*0,5 = 3,14

- Grillage weight, kg- 0.4 m.*0.5 m.*30 m.*2500kg/m 3 = 19500

- Weight of supports, kg- 21 * 3 m * 0.196 m 2 * 2500 kg/m 3 * 1.3 = 40131

- Weight of the building, t- Weight of supports + weight of grillage + sum from the table ≈ 224

To calculate the volume of the grillage and other parameters, it is necessary to determine the mass of the structure without foundation supports. As a result, we obtain M = 204 tons. The width of the salting is equal to M / (L * R) = 204/ (30*75) = 0.09 m. Such a belt cannot be used for construction, in this case, since the overhangs of brick walls should not be more than 40 mm. Therefore, we set the width to 400 mm, but the height remains 500 mm.

Article

Any structure needs a reliable, high-quality, well-designed and equipped foundation. Today, a grillage foundation on piles is very popular, which has economic benefits compared to a traditional strip foundation. A special feature of the design is the horizontal lintel connecting the piles. Grillage: what it is and what its main purpose is, is described in detail in the article.

It is necessary to begin to consider this issue with a definition: what is a foundation grillage. The internal building element is a horizontal concrete, steel or wooden lintel that connects the disparate elements of a columnar or pile foundation with each other, resulting in the creation of a flat platform for installation of the flashing crown. The grillage takes the load from the load-bearing structures of the building and evenly distributes it to the supports, which transmit the load to the ground.

This design is not inferior in its rigidity and strength to a traditional strip foundation, but the price of a grillage foundation will be much lower, which is associated with less labor and labor intensity.

The foundation structure is created using frame technology, where pillars or piles are tied together to form a strong foundation. A foundation with a grillage is constructed on clay, peat, loess-like, loamy, heaving and silty soils. The construction of a house can be carried out in areas with ornate terrain or on slopes.

Types of grillage and what types it has

The ergonomics, durability and aesthetics of the building depend on the type of grillage that is laid on a columnar or pile foundation. It can be slab, strip and glass.

Depending on the location of the grillage relative to the subgrade, the following types of structures are distinguished:

- increased;

- high;

- recessed

The jumper design can be:

- monolithic;

- prefabricated monolithic;

- national team.

Depending on the material of manufacture, grillages are distinguished:

- metal;

- wooden;

- concrete;

- reinforced concrete.

Types of element and the main task of the grillage

The main purpose of the grillage is to absorb the load from the load-bearing elements of the building and distribute it evenly on the foundation. The most common and economically justified is a pile foundation.

A slab grillage on piles in the form of large-format reinforced concrete slabs is installed with significant dimensions of the building along its perimeter. This grillage is placed on a standard pie consisting of:

- sand and gravel cushion in the form of two layers of 10 cm each with vibration compaction;

- ring drainage located at the level of the grillage base;

- concrete preparation in the form of a screed without reinforcement;

- waterproofing.

Strip foundations on piles can be monolithic or prefabricated. The first option is used for bored piles. This is due to the fact that the materials have the same linear expansion and technical characteristics. It is also easier to wall up the heads with protruding reinforcement in the body of the grillage.

Prefabricated strip grillage is used in wood construction technology. Wooden beams are laid on the heads and joined into half a tree. This allows you to reduce construction costs and begin construction of the structure the very next day after laying the foundation.

A prefabricated strip grillage can be made in the form of reinforced concrete beams adjacent to the pile cap. This design is used primarily for screw piles tied with I-beams or channels.

When installing reinforced concrete bored piles with a grillage, a glass type of structure can be used. The grillage is represented by a kneecap mounted on a pole, a multiple of 15 cm in height and 30 cm in width. Each glass must be supported by four piles. This type of base is used when installing columns. Most often used in agricultural and industrial construction.

What is a grillage: element design

A monolithic grillage is the most successful solution for low-rise construction. The element is represented by a solid closed-type structure made of reinforced concrete or concrete. It is poured during construction, in the form of a monolithic slab or beam (ribbon). In the first option, the design connects all the piles into a single system that covers the entire area of the building. The tape grillage connects the piles in series and is installed only under the load-bearing elements of the building.

The grillage, securely fixed to the piles and incorporating them into its thickness, connects the base elements. A monolithic strip grillage can be raised, high or recessed. It is arranged under unfavorable geological soil conditions. The implementation of such a grillage is distinguished by high technical and operational characteristics. However, the design has increased labor intensity, high cost of work and requires the creation of dense reinforcement.

The prefabricated grillage is represented by a structure made of steel beams connected to each other by welding. I-beams and beams are used as connecting elements. The structure can also be made of wooden beams. This option is used mainly for the construction of non-permanent structures and industrial buildings. The structure is mounted and secured to the pile heads, which does not require subsequent embedding.

Helpful advice! It is not advisable to use a prefabricated grillage for the construction of a private house, since this is associated with a very labor-intensive and costly process.

The prefabricated type also has its disadvantages. First of all, the installation process is very labor-intensive, which is associated with the significant weight of the metal elements. In some places of the grillage, areas with low strength may form, which is associated with the low rigidity of the welded joints. Due to the formation of corrosion or rotting of wood, the structure is short-lived, which is limited to 1020 years of operation.

An intermediate solution between the two previous options is a monolithic prefabricated grillage. A prefabricated structure consists of prefabricated parts that are laid on piles and connected to each other with a key joint. This is done during construction. Then the entire structure is monolithic.

Optimal grillage location

The most rational solution from the point of view of the integrity of the structure and the stability of its operation in the event of various deformations is considered to be the installation of a high or hanging grillage on bored piles. It is installed above the ground level at least 10 cm. If the distance is less, there is a possibility of damage to the integrity of the grillage and the nodes connecting it to the piles, which will lead to the tearing out of the latter.

The main disadvantage of this design is the lack of sealing of the space between the lower part of the grillage and the ground. Due to the fact that free access of cold air is created, heat loss in the house increases. The problem can be solved by installing panels or additional insulation of the floor of the house.

Helpful advice! It is advisable to choose this type of grillage for a subtropical climate, also when constructing wooden structures.

The base of the raised grillage is located at the ground level, on which a gravel or sand cushion 10-15 cm thick is laid, for which a layer of soil is removed. This layer helps reduce soil moisture under the building and freely filter water. This option eliminates the formation of a blown area between the ground and the ceiling.

A recessed strip foundation on bored piles is the most popular option, but at the same time the most irrational. To create it, a shallow trench is dug around the perimeter of the future building. Next, the piles are installed so that their heads protrude from the bottom of the trench. A sand cushion is installed. After this, a formwork trough is made, the bottom of which is located below ground level. Next, a concrete grillage is created.

Helpful advice! Despite the fact that a windproof space is formed under the recessed grillage, centerboards can be installed as additional insulation, which will take the load from heaving soil during frosts.

What material is the grillage made of?

Reinforced concrete grillage is characterized by increased strength, reliability, stability, rigidity, load-bearing capacity and durability. This is the most common option. The structure contains reinforcement, which increases the strength characteristics of the grillage, taking on part of the load. Reinforcement can be performed by creating a full-fledged spatial frame or laying individual rods.

Important! When forming a reinforced concrete grillage, a sufficient protective layer for the reinforcement must be provided.

The production of a concrete grillage is identical to the previous option. The difference is the lack of reinforcement. The entire load is absorbed by a concrete structure that covers the pile heads to a height of at least 10 cm. This option is less strong and durable. Concrete grillage is used in the construction of one-story buildings.

The production of a metal grillage is carried out from rolled profiles, represented by I-beams and channels. The result is a strong and rigid structure. But due to possible corrosion of the metal, especially in places of welded joints, the metal grillage is short-lived. It is used for the construction of one-story buildings.

Characteristics of a pile foundation with a grillage

A pile foundation is a structure in which the load on the ground from a structure is transmitted through piles, which are represented by pillars or beams partially or completely buried in the ground. For a rigid and reliable connection of the upper parts of the piles, a grillage is installed. It is rational to use this type of foundation when constructing buildings on water-saturated soft soils, on slopes with a steep slope, in areas where the depth of soil freezing exceeds 2 m, and also if the weight of the future structure exceeds 350 tons.

Related article:

Drainage system around the house: drainage device for the foundation of a residential building

Drainage device to protect the foundation part of the building, the specificity of this procedure, the technology for creating a structure with your own hands.

Piles are metal, wood or concrete pointed, long or heeled rods of round or square cross-section. They are immersed in the ground in finished form or made directly into the soil. In its finished form, the pile has a sharp end on one side, with which, with the help of special construction equipment, it is immersed into the thickness of the soil, passing through moving layers, and rests on solid soil. When making piles, holes are drilled in the ground, which are subsequently reinforced and filled with concrete.

Types of pile foundations with grillage

Depending on the method of immersion into the ground, a pile foundation can be driven, driven or screwed. The first option is represented by concrete or reinforced concrete structures. To create them, the reinforcement is prestressed, which increases the crack resistance of the foundation. To install piles in the thickness of the earth, it is necessary to drill the required number of holes of a given diameter and depth. A casing metal or concrete pipe is inserted into each of them. The reinforcement is lowered into it and the entire cavity is filled with concrete.

The design can be made with a closed or open lower end. The main advantage of this type of pile foundation is its high load-bearing capacity, simple technology, reduced cost of work, which is associated with minimal labor costs, and the absence of negative impacts and vibrations on surrounding structures.

The second option involves driving ready-made reinforced concrete piles into the ground. As special equipment, pile drivers, vibratory hammers and hydraulic pile-pressing units can be used, the choice of which depends on the characteristics of the soil, the features and depth of driving piles. This type of foundation is used in permafrost zones. The driving elements can be round, square or trapezoidal. To increase reliability and load-bearing characteristics, piles can be equipped with additional support rings.

Screw grillage foundation: what is it?

A foundation with a grillage on screw piles is one of the new options. The design has good performance characteristics and can be installed on any type of soil. The pile is represented by a hollow pipe, a sharp tip and one or more blades. The tip can be welded or cast.

For each type of soil, a certain type of screw piles is used. For stone areas, narrow-bladed screw piles are used, which have especially strong welded tips and double blades, which ensure reliable adhesion to the ground and prevent the pile from skewing. For thawed and waterlogged soils, piles with a sharp cast tip and medium-sized blades are used, which guarantees easy penetration of the element into the soil without loosening it.

For permafrost soils, piles with small blades are used, which facilitates the rapid introduction of the element into the soil without the risk of distortion. The tip of the pile has a special cutter made of especially strong alloy steel. Such elements are highly expensive.

Options for the location of piles and their types

Piles can be hanging or in the form of racks. In the first option, the load on the surrounding soil is transmitted through friction against the side walls. Such piles are characterized by a developed lateral surface along the entire length with many protrusions, which ensures good load-bearing capacity of the structure. This type is used for soils with a high groundwater level or having a thick layer of weak soil, under which there is a stronger one, but it is still not able to support the rack pile.

Rack piles transfer the load from the structure directly to the strong soil, which is located under the weak layer. The elements are characterized by a smooth surface to which the soil does not cling. The most important criterion for this type of pile is a wide base, which can bear more than 80% of the total load.

Helpful advice! For multi-storey and durable buildings, it is advisable to choose TISE rack piles, which have a significant widening in the lower part of the element, which eliminates further settlement.

Piles in the ground can be located in one of the following ways:

- single;

- tape;

- stripes;

- in the form of a bush;

- field.

The first method is selected for a free-standing support. Depending on the terrain, the pile can be installed inclined. The tape method involves placing piles along the entire perimeter of the structure. For the construction of massive multi-story structures, piles are installed in several rows in the form of strips.

Cluster placement involves installing elements under load-bearing walls and objects with heavy loads. This method is used for the construction of canopies and structures with a large number of columns that hold the roof. For large buildings, piles are installed in a checkerboard pattern.

The choice of pile placement method depends on the construction project. Elements should be located in corners and at the intersections of piers. The optimal distance between piles in a grillage is 2–3 m.

Pros and cons of a pile-grillage foundation

When choosing a foundation for a future structure, it is necessary to study the pros and cons of a pile foundation with a grillage. This design has excellent stability and high load-bearing capacity. This is especially important for building houses on soils that are prone to movement. This type of foundation is often found in seismically active areas, where the foundation will remain motionless during small earthquakes.

Important! Classic piles can withstand loads of up to several tons.

It is advisable to choose a pile-grillage foundation for the construction of structures on soils with a complex structure, especially in mountainous areas, which are characterized by a small layer of loose soil. Manufacturers produce piles of various lengths, which allows you to build foundations on slopes, as well as create curved objects. A pile-grillage foundation is an ideal foundation for the construction of a building from any material.

Due to the fact that the grillage is not in contact with the ground, the possibility of flooding of the structure with groundwater and rodents and various insects entering the house is eliminated. To erect a pile foundation with a grillage, there is no need for preliminary cleaning and leveling of the construction site, which reduces the labor intensity and cost of work. You can build the foundation yourself without using powerful construction equipment, which is especially important in densely built areas or on small plots of land.

However, this design has its drawbacks. When designing this type of foundation, accurate calculations should be performed with the assistance of a specialist. Here you should take into account the length, diameter, weight, number of piles and their exact location.

Important! Pile foundations are not recommended for use for heavy, massive structures, even by increasing the diameter of the pile elements.

Another disadvantage is the labor-intensive repair of the foundation, which will require the construction of retaining walls or the installation of additional piles. The construction of a pile foundation with a grillage eliminates the need for a basement and requires additional insulation of the lower part of the building.

Calculation of pile-grillage foundation

Calculating a pile-grillage foundation is a serious and responsible undertaking. This process is best left to a specialist in this field. To perform the calculation, it is necessary to collect information about the territory for construction: geological structure and physical properties of the soil, hydrogeological and physical-geographical conditions of the area. You can obtain all the necessary information from your local geological exploration service by placing an order in advance.

Based on the data obtained, calculations of the parameters of the selected foundation are performed. The load on the foundation with a grillage is calculated based on the total mass of the structure. Next, the depth of the supports is calculated. Based on the bearing capacity of the foundation and the magnitude of the load, the minimum total area of the supports is determined. Next, the type, diameter and number of piles are selected, which are distributed over the area of the building, according to the selected layout. Next, the dimensions of the grillage are determined by calculation.

Helpful advice! To calculate a pile foundation with a grillage, you can use online calculators or the services of specialists from construction companies.

The calculation of the pile foundation grillage is carried out on the basis of SNiP II-B.1–62. It should be taken into account that the width of the structure should be 10–20 cm thicker than the wall of the building, and the height should be approximately equal to the width. The final stage is the selection of building materials.

Installation of a pile-strip foundation with your own hands

Constructing a grillage on a columnar or pile foundation with your own hands is a feasible and feasible task. It is advisable to choose the first option for the construction of small structures without constant load, such as country houses and gazebos. Pile foundations are the most popular solution for the construction of buildings intended for permanent use.

It is advisable to construct a pile-grillage foundation with your own hands in late spring, early summer or early autumn. The first step is to prepare the site by clearing it of debris and vegetation.

Helpful advice! It is recommended to treat the area for future construction with chemicals, which will prevent the growth of vegetation.

Next, the territory is marked based on the project, indicating the location of the piles. If screw piles are used, they should be screwed in without first creating holes. To do this, you can use a pipe or a crowbar, which must be inserted into the head of the support. For screw piles, it is more convenient to make a metal or wooden grillage. It is advisable to install a concrete lintel only under a future house made of stone, which requires high rigidity of the base.

Important! The piles must be positioned strictly perpendicular to the ground.

If you are installing bored piles, you will not be able to install them yourself. To create holes in the ground, you need to use special equipment. Bored piles can be made in two ways. The first option involves placing formwork in the form of a metal pipe of the required diameter in each drilled hole. The internal space is reinforced and filled with concrete. The second option eliminates the installation of formwork.

To construct a pile foundation with a grillage, class B7.5-B15 concrete is used, which is the optimal solution for small buildings. For large buildings, concrete of class up to B25 can be used. It is not advisable to use a more durable building material for private housing construction. This is not economically justified, since the safety factor of the material exceeds the load from the building. Reinforcement with a diameter of 12-16 mm of class A400 is placed in each hole.

Laying a pile foundation with a monolithic grillage

For the work you will need the following tools and materials:

- bayonet and picking shovel;

- stakes;

- rope;

- wooden boards or chipboard sheets for formwork;

- set of steel screw piles;

- fittings for reinforcing piles and grillage;

- metal pipes;

- concrete solution;

- plumb line;

- level or hydraulic level;

- roulette;

- specialty chemicals;

- foam boards;

- sand;

- crushed stone;

- bitumen mastic.

The construction of a pile foundation with a monolithic grillage is carried out according to the following algorithm:

- cleaning and leveling the base;

- drilling holes in designated locations of the required depth and size for piles;

- compacting the soil and creating a cushion of medium or coarse sand 30-50 cm thick at the bottom of the holes;

- installation of screw or bored piles according to the work technology;

- preparing a sand cushion for a monolithic grillage;

- formwork installation;

- a frame made of reinforcement is lowered into the pit, consisting of at least 4 rods, the length of which is selected taking into account the height of the strapping;

- performing concrete pouring;

- creation of wooden formwork for a monolithic grillage;

- after the concrete has hardened, the reinforcement frame for the grillage is assembled;

- installation of formwork for strapping;

- concreting the grillage;

- removing the formwork after the concrete has gained the required strength;

- performing waterproofing.

Helpful advice! If an underground space is formed, it is better to cover it with a decorative base or fence.

The grillage is reinforced using rods of class A400, which can be joined into a frame by welding or tied using binding wire. The second option is more labor-intensive, but reliable. When laying the frame, you should leave a distance from the rod to the formwork of at least 3 cm - to create a protective layer of concrete, which will prevent the formation of corrosion.

Helpful advice! At the corners of the building, reinforcement bars must be tied with wire.

Creation of a monolithic foundation grillage on piles

Before installing the grillage, a layer of waterproofing should be laid on the piles. This is necessary in order to eliminate the possibility of the soles of the elements getting wet. Roofing felt, polyethylene films or membranes can be used as a waterproofing material. If a cushion of fine gravel is provided under the base of the grillage, which may compromise the integrity of the waterproofing layer, a concrete footing should be provided.

The next stage is the installation of formwork for the foundation on concrete piles. To do this, markings are carried out in increments of 0.5-0.8 m with driving in pegs with a cross-section of 5x5 cm along the entire perimeter of the building. Next, horizontal wooden boards are laid, in which holes for the piles are pre-cut.

Vertical formwork elements are installed and nailed to horizontal boards. For formwork, it is recommended to use durable wooden boards or chipboard sheets. The inside of the prefabricated formwork should be covered with plastic film. The dimensions of the formwork must exceed the height of the future grillage by at least 5 cm.

Helpful advice! In the case of a low grillage, you can use permanent formwork, which will subsequently become additional thermal insulation for the walls of the premises.

Grillage reinforcement: step-by-step instructions

The next step in constructing a pile foundation grillage is the creation of a reinforcement frame, which must subsequently be completely recessed into concrete on all sides. To do this, it is necessary to lay wooden blocks of any width on the bottom of the formwork in the transverse direction, but with the same thickness of 30-50 mm. The bottom row of reinforcement bars is laid on them, which must be tied together so as to ensure the same distance between the rods.

The upper chord of the reinforcement cage must be suspended from the transverse beams that connect the formwork posts. Then you should tie the lower and upper belts together.

For reinforcement of monolithic tape, class A400 reinforcement is usually used. The number of rods is calculated based on the ratio of the cross-sectional area of the horizontal lintel to the sum of the cross-sections of all rods, which is 1000:1. The following calculation procedure is performed:

- it is necessary to multiply the width by the height of the grillage, dividing the result by 1000;

- the resulting value must be divided by the cross-sectional area of one rod.

The result obtained is the minimum number of bars required for reinforcement.

Helpful advice! The distance between rows of reinforcement should not exceed 150 mm.

Installation of additional elements and concreting the grillage

Before pouring concrete on a horizontal lintel, special pipes should be laid through which utilities will pass, such as water supply, heating, sewerage and communications. Ventilation holes should also be provided in the base.

Important! This stage should not be neglected, since then the integrity of the grillage will have to be compromised.

To create a monolithic grillage, it is recommended to use concrete grades M300 and M500. When filling the formwork with concrete mixture, you should use a vibrating machine that can shake the concrete to eliminate the possibility of cavities, which will increase the strength characteristics of the concrete.

Two hours after pouring the concrete, it is recommended to cover it with film. If it is hot outside, it is periodically necessary to remove the film and moisten the concrete with water so that cracks do not form on its surface. Complete hardening of the structure will not occur earlier than in a week, which depends on the ambient temperature.

If the outside temperature reaches 20 degrees, the formwork can be removed after 4 days, since the concrete base will gain more than half its strength. If the temperature does not rise above 10 degrees, the formwork does not need to be touched for 14 days. When the air temperature is below 10 degrees. it is necessary to provide additional heating and organize insulation of the foundation. After the concrete has completely hardened, you can begin to create a waterproofing layer using bitumen mastic.

Construction of a columnar foundation with a grillage

The construction of the foundation for future construction is carried out according to the following algorithm:

- clearing the area of vegetation followed by treatment with chemicals;

- marking the site based on the project;

- creating holes for future pillars;

- compacting soil at the bottom of the pit;

- creating a sand cushion at least 15 cm high;

- laying geotextiles;

- backfilling with crushed stone;

- performing formwork for each pit;

- covering the formwork system with polyethylene;

- creating a frame for reinforcing piles;

- forming pillars by pouring concrete into holes;

- treating the surface of the pillars with bitumen mastic;

- installation of formwork between reinforced concrete pillars to create a grillage, the height of which should exceed the height of the future structure by 5-10 cm;

- sand cushion device;

- concreting the grillage with structural reinforcement;

- creation of hydro- and thermal insulation.

The main mistakes when constructing a pile-grillage foundation

The first mistake that can significantly affect the reliability and rigidity of the structure is incorrect calculation of the load on the base of the building. Here it is very important to take into account the peculiarities of the type of soil of the area where construction will be carried out.

The next mistake is considered to be small depth or incorrect installation of piles. Free space may form in the soil under the piles, which will cause shrinkage of the foundation. This will undoubtedly lead to a decrease in the air gap under the grillage, which can cause the pile to break in the winter. To eliminate this possibility, piles should be installed below the freezing depth of the soil.

In practice, there are cases where the design does not provide for the creation of an air gap under the grillage. This is especially dangerous in the winter, when the frozen ground expands significantly in different directions, including vertically. This will lead to the formation of excess pressure on the bottom of the grillage, which may cause damage or breakage. To eliminate this, care should be taken to organize an insulating layer in the form of polystyrene foam boards, which will also act as artificial shock absorption.

An equally important point is the creation of a reliable connection between the grillage and the piles. If there is no reliable fixation, this can lead to horizontal displacement of the pillars. As a result, they will not be affected by the design load from the structure, which may sag in this place.